CNC Lathe Services in San Jose: High-Quality Precision Machining

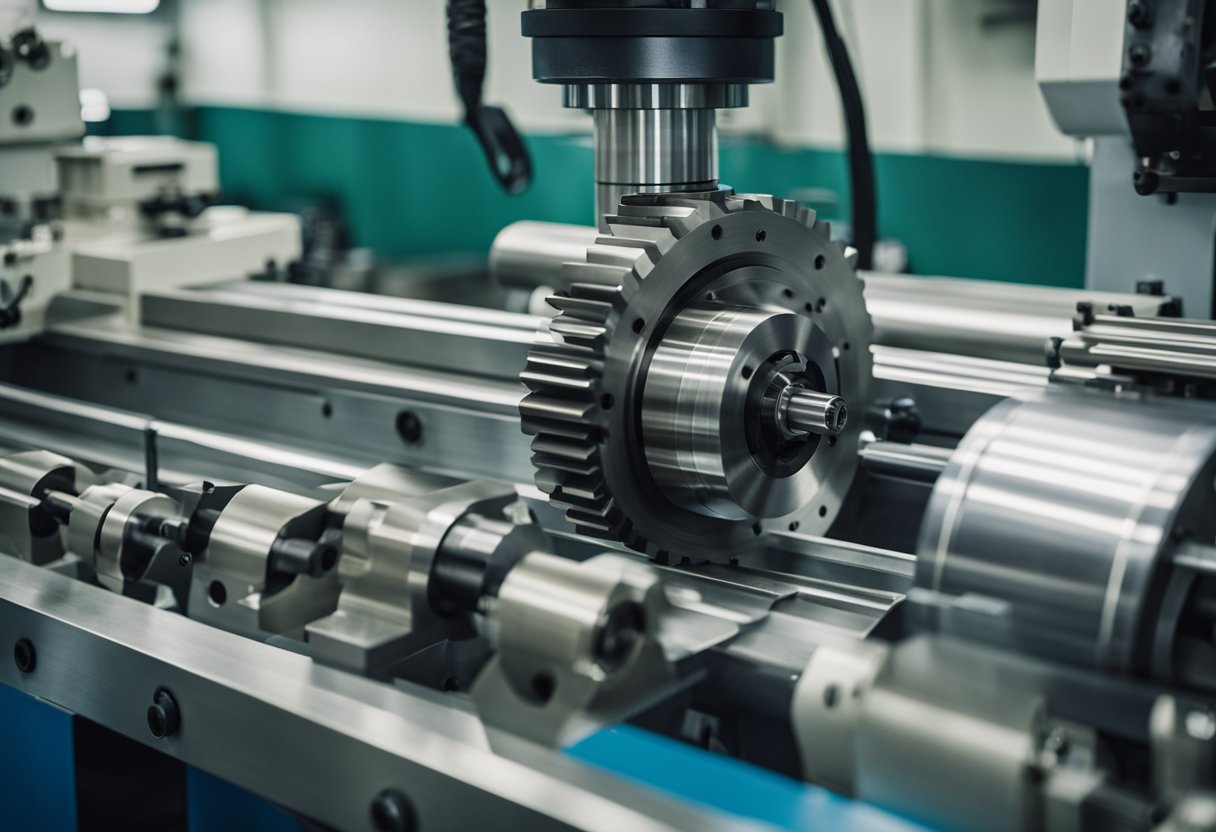

A CNC lathe is a machine tool used in the manufacturing industry to produce precision components. It is a computer-controlled machine that uses rotating tools to remove material from a workpiece to create the desired shape. San Jose, California is home to many CNC machine shops that specialize in the production of high-quality precision components using CNC lathes.

These machine shops in San Jose offer a wide range of services, including CNC turning, milling, drilling, and grinding. They use state-of-the-art equipment and software to ensure that every component they produce meets the exact specifications of their clients. With years of experience and expertise, they are able to provide reliable and efficient solutions for a variety of industries, including aerospace, automotive, medical, and more.

If you are looking for a CNC machine shop in San Jose, California, you can be confident that you will find a reliable and knowledgeable partner for your manufacturing needs. With the latest technology and a team of skilled professionals, these machine shops are able to deliver precision components that meet the highest standards of quality and performance. Whether you need a single prototype or a large production run, they have the expertise and resources to get the job done right.

Understanding CNC Lathe Capabilities in San Jose

CNC lathes have revolutionized the manufacturing industry, providing a level of precision and efficiency that was once unimaginable. San Jose is home to a number of CNC lathe service providers that offer a wide range of capabilities to meet the diverse needs of their clients. This section will explore some of the key capabilities of CNC lathe services in San Jose, including precision and materials, equipment and technology.

Precision and Materials

One of the primary benefits of CNC lathe services is their ability to produce parts with a high degree of precision. CNC lathes use computer-controlled cutting tools to produce parts that are accurate to within a few thousandths of an inch. This level of precision allows for the production of complex parts with tight tolerances and intricate geometries.

CNC lathe services in San Jose work with a variety of materials, including metal, plastic, wood, Kovar, Invar, aluminum, brass, stainless steel, and copper. Each material has its own unique properties and requires specialized tools and techniques to machine effectively. CNC lathe service providers in San Jose have the expertise and equipment necessary to work with a wide range of materials, ensuring that they can meet the needs of their clients regardless of the material being used.

Equipment and Technology

CNC lathe services in San Jose use state-of-the-art equipment and technology to produce high-quality parts with a high degree of precision. They use a variety of cutting tools, including drills, end mills, and reamers, to produce parts with complex geometries and tight tolerances. They also use advanced software programs to program and control the CNC lathes, ensuring that each part is produced exactly as intended.

In addition to traditional CNC lathes, some service providers in San Jose also offer multi-axis CNC lathes, which are capable of producing even more complex parts with greater precision. These machines can produce parts with multiple features on a single setup, reducing cycle times and increasing efficiency.

Overall, CNC lathe services in San Jose offer a wide range of capabilities to meet the needs of their clients. With their expertise, equipment, and technology, they can produce high-quality parts with a high degree of precision from a variety of materials.

Industries Served by San Jose CNC Lathes

San Jose CNC Lathes serve a wide range of industries, from aerospace and automotive to medical and biotech, as well as semiconductor and electronics. Here are some of the industries that benefit from the precision and efficiency of CNC lathes.

Aerospace and Automotive

The aerospace and automotive industries require high-quality and precise parts to ensure safety and reliability. San Jose CNC Lathes are capable of producing complex and intricate parts with tight tolerances, which are essential for the aerospace and automotive industries. With CNC lathes, these industries can produce parts with high accuracy and repeatability, which is crucial for maintaining consistency in their products.

Medical and Biotech

The medical and biotech industries require precise and accurate parts for medical devices and equipment. CNC lathes are capable of producing parts with high precision and accuracy, making them ideal for the medical and biotech industries. With CNC lathes, these industries can produce parts with complex geometries and tight tolerances, which are essential for medical devices and equipment.

Semiconductor and Electronics

The semiconductor and electronics industries require precision parts for their products. CNC lathes are capable of producing parts with high accuracy and repeatability, making them ideal for the semiconductor and electronics industries. With CNC lathes, these industries can produce parts with complex geometries and tight tolerances, which are essential for their products.

In conclusion, San Jose CNC Lathes serve a wide range of industries, from aerospace and automotive to medical and biotech, as well as semiconductor and electronics. With their precision and efficiency, CNC lathes are essential for producing high-quality and precise parts, which are crucial for maintaining consistency and reliability in various industries.

Advanced Machining Processes and Services

CNC Milling and Turning

CNC milling and turning are essential processes in the manufacturing industry. CNC lathe San Jose offers high-quality CNC milling and turning services that are designed to meet the needs of various industries. They use advanced machinery and equipment to provide precision machining services that meet the specific requirements of their clients.

Their CNC milling services are ideal for producing complex parts with high precision and accuracy. They use advanced CAD/CAM software such as Solid Works and Autodesk Inventor to create 3D models of the parts and then use their 5-axis machining capabilities to produce the parts with high accuracy.

Their CNC turning services are ideal for producing cylindrical parts with high precision and accuracy. They use advanced machinery and equipment to produce parts with tight tolerances and high surface finishes.

5 Axis Machining and Inspection

CNC lathe San Jose offers precision 5-axis machining services that are ideal for producing complex parts with high precision and accuracy. They use advanced machinery and equipment to produce parts with tight tolerances and high surface finishes.

Their 5-axis machining services are ideal for producing parts with complex geometries and shapes. They use advanced CAD/CAM software such as Solid Works and Autodesk Inventor to create 3D models of the parts and then use their 5-axis machining capabilities to produce the parts with high accuracy.

They also offer inspection services using Zeiss CMM machines to ensure that the parts meet the required specifications. They use advanced inspection techniques to ensure that the parts are produced with high precision and accuracy.

In summary, CNC lathe San Jose offers advanced machining processes and services that are designed to meet the needs of various industries. They use advanced machinery and equipment to provide precision machining services that meet the specific requirements of their clients. Their CNC milling and turning services are ideal for producing complex parts with high precision and accuracy, while their 5-axis machining services are ideal for producing parts with complex geometries and shapes. They also offer inspection services using Zeiss CMM machines to ensure that the parts meet the required specifications.

Choosing a CNC Lathe Provider in San Jose

When it comes to finding a CNC lathe provider in San Jose, there are several factors to consider. It is important to choose a provider that offers quality and consistency, has local expertise and a reliable supply chain, and holds necessary certifications.

Quality and Certifications

Quality is a critical factor when choosing a CNC lathe provider. Look for a provider that has ISO 9001:2015 certification, which demonstrates their commitment to quality management systems. This certification ensures that the provider has established and maintains a high level of quality in their processes and products.

In addition to certifications, it is important to consider the experience and expertise of the provider. Look for a provider who has a team of skilled machinists and has experience working with a variety of materials. This will ensure that they can handle any project with precision and accuracy.

Local Expertise and Supply Chain

Choosing a provider with local expertise can provide several benefits. They will have a better understanding of the local market and can offer personalized service. Additionally, a provider with a reliable supply chain can ensure that your project is completed on time and within budget.

Look for a provider that has experience working with other businesses in the San Jose, Bay Area, and Silicon Valley regions. This will ensure that they understand the unique needs of local businesses and can offer tailored solutions.

Prices

While quality and expertise are important, it is also important to consider pricing. Look for a provider that offers competitive pricing without sacrificing quality. It is important to get a quote upfront and ensure that there are no hidden fees or charges.

AC Manufacturing is a precision CNC machine shop located in San Jose, CA. They offer a range of services, including CNC turning and milling, and have experience working with a variety of materials. They hold ISO 9001:2015 certification and have a team of skilled machinists. AC Manufacturing is committed to providing quality products and personalized service to businesses in the San Jose, Bay Area, and Silicon Valley regions.

Frequently Asked Questions

What factors contribute to the cost of CNC lathe services in San Jose?

The cost of CNC lathe services in San Jose depends on several factors, including the complexity of the project, the materials used, and the level of expertise required. Additionally, the size and capacity of the CNC lathe can also affect the cost. Generally, larger and more advanced CNC lathes will be more expensive to operate and maintain, which can result in higher service costs.

How do CNC lathes compare to traditional lathes in terms of precision and efficiency?

CNC lathes are generally more precise and efficient than traditional lathes. This is because CNC lathes use computer-controlled systems to guide the cutting tool, which allows for more accurate and consistent results. Additionally, CNC lathes can often complete projects more quickly than traditional lathes, which can result in faster turnaround times and lower costs.

What are the most reputable CNC lathe service providers in the San Jose area?

There are several reputable CNC lathe service providers in the San Jose area, including [insert company names here]. These companies have a proven track record of providing high-quality CNC lathe services to a wide range of clients, and they are known for their expertise, reliability, and customer service.

What should one consider when purchasing a used CNC lathe in San Jose?

When purchasing a used CNC lathe in San Jose, it is important to consider several factors, including the age and condition of the machine, the level of maintenance it has received, and the reputation of the seller. Additionally, it is important to ensure that the machine is compatible with the specific needs of the buyer, including the size and complexity of the projects they will be working on.

How does the size of a CNC lathe affect its functionality and suitability for small-scale projects?

The size of a CNC lathe can have a significant impact on its functionality and suitability for small-scale projects. Smaller CNC lathes are generally better suited for smaller projects, as they are more precise and can produce more detailed results. Larger CNC lathes, on the other hand, are better suited for larger projects, as they can handle larger workpieces and can often complete projects more quickly.

What are the common maintenance requirements for CNC lathes to ensure optimal performance?

Common maintenance requirements for CNC lathes include regular cleaning and lubrication, as well as periodic inspections and repairs. Additionally, it is important to ensure that the cutting tools are properly sharpened and replaced when necessary, and that the machine is calibrated regularly to ensure optimal performance.