Lathe MC San Jose: A Comprehensive Guide to CNC Lathes in San Jose

Lathe MC San Jose is a company that specializes in precision machining services. Located in the heart of San Jose, California, the company has been providing top-notch machining solutions to clients in the Bay Area and beyond for many years. With a team of experienced professionals and state-of-the-art equipment, Lathe MC San Jose is able to deliver high-quality products that meet the exact specifications of its clients.

Precision machining is a critical process in the manufacturing industry, and Lathe MC San Jose is at the forefront of this field. The company's expertise in CNC machining, turning, milling, and other precision machining techniques has earned it a reputation as a reliable and efficient provider of machining services. Whether it's a small prototype or a large-scale production run, Lathe MC San Jose has the knowledge and resources to get the job done right. Clients can expect fast turnaround times, competitive pricing, and exceptional customer service when working with this reputable company.

Understanding Lathe Machining

Lathe Fundamentals

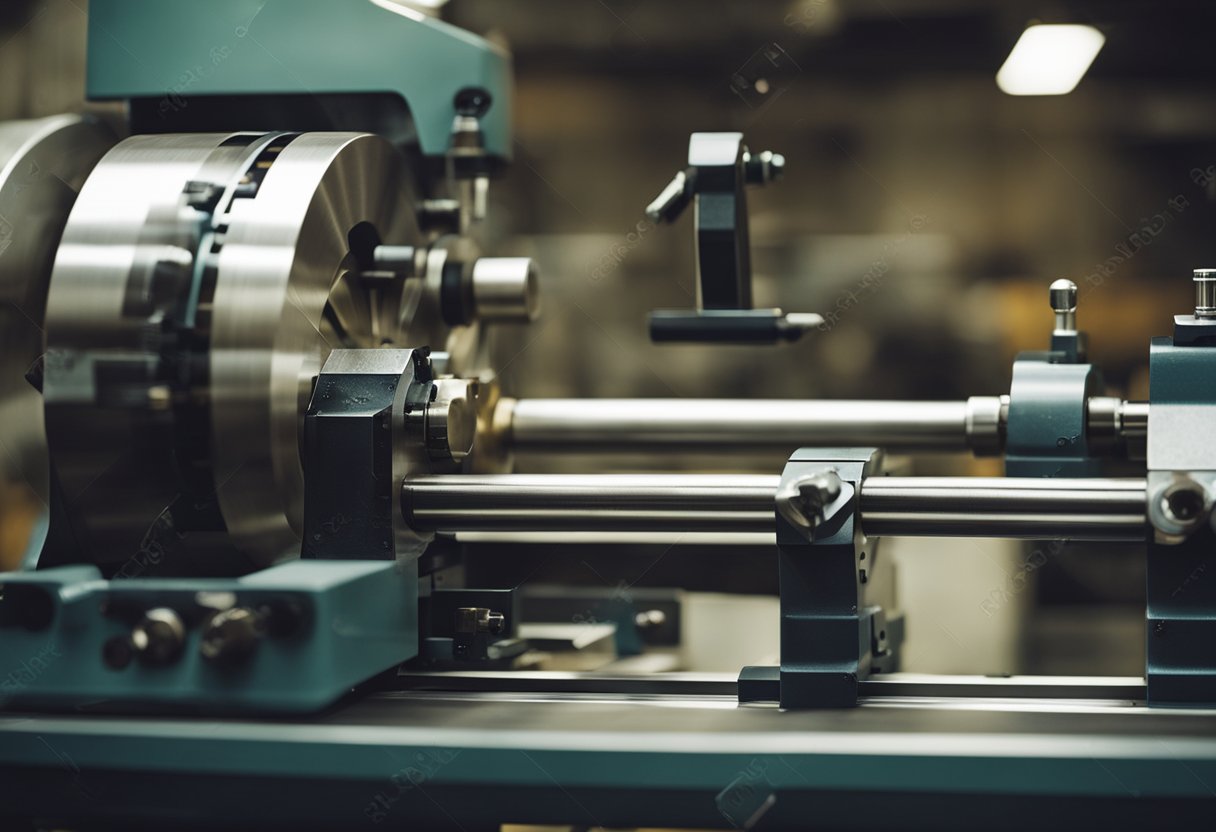

Lathe machining is a precision metalworking process that involves turning a workpiece on a spindle to shape it into a desired form. The lathe is a versatile machine tool that can be used for a wide range of applications, from simple cylindrical shapes to complex parts with intricate details.

In lathe machining, the workpiece is secured on the spindle, which rotates at a high speed while the cutting tool moves along the workpiece to remove material and create the desired shape. The cutting tool can be moved in different directions and angles to achieve the desired results.

Types of Lathes

There are several types of lathes available for different applications, including engine lathes, turret lathes, and CNC lathes. Engine lathes are the most common type of lathe and are used for general-purpose machining. Turret lathes are used for high-volume production of small parts, while CNC lathes are computer-controlled and can be programmed to produce complex parts with high precision.

Lathe Components

A lathe consists of several components, including the spindle, chuck, tailstock, and cutting tool. The spindle is the main rotating component that holds the workpiece, while the chuck is used to secure the workpiece to the spindle. The tailstock is used to support the other end of the workpiece and can be adjusted to accommodate different lengths. The cutting tool is mounted on a tool post and can be moved in different directions to remove material from the workpiece.

In conclusion, understanding the fundamentals of lathe machining, the types of lathes available, and the components that make up a lathe is essential for anyone interested in precision metalworking and turning. With the right knowledge and skills, a lathe can be used to create complex parts with high precision and accuracy.

Materials and Precision

Material Selection

The selection of materials plays a critical role in the performance and durability of lathe machine components. Lathe MC San Jose uses a variety of materials, including kovar, invar, aluminum, brass, and plastics, to manufacture their machines. Each material is chosen based on its unique properties and suitability for the intended use.

Kovar and invar are popular choices for lathe machine components due to their low coefficient of thermal expansion and high dimensional stability. These materials are commonly used for precision parts that require tight tolerances and minimal distortion under varying temperatures.

Aluminum and brass are lightweight and offer excellent machinability, making them ideal for applications that require high-speed machining. Plastic materials, such as nylon and acetal, are also commonly used for non-critical components due to their low cost and ease of fabrication.

Precision and Tolerances

Lathe MC San Jose places a strong emphasis on precision and tight tolerances in their manufacturing processes. The company uses advanced CNC machines and inspection equipment to ensure that each component meets the required specifications.

Tight tolerances are particularly important for critical components such as spindle bearings, which require precise alignment and minimal runout to ensure smooth operation and long service life. Lathe MC San Jose also employs skilled machinists who are trained to operate the machines and perform quality checks to ensure that each component meets the required specifications.

Overall, the combination of high-quality materials and precision manufacturing processes allows Lathe MC San Jose to produce reliable and durable lathe machines that meet the needs of a variety of industries.

Production and Manufacturing

CNC Machining

Lathe MC San Jose utilizes modern CNC machining techniques to increase productivity and achieve high precision in their production machining processes. With state-of-the-art equipment and experienced machinists, they are able to produce complex parts with tight tolerances and consistent quality.

Their CNC machining capabilities include turning, milling, drilling, tapping, and more. They are equipped to handle a wide range of materials, including aluminum, steel, brass, copper, and plastics.

Quality Assurance

Quality assurance is a top priority at Lathe MC San Jose. They have a rigorous quality control process in place to ensure that every part they produce meets the highest standards of quality and accuracy. This includes regular inspections throughout the production process, as well as final inspections before parts are shipped to customers.

Their quality control team is highly trained and experienced in using advanced measurement tools and techniques to verify the accuracy and quality of each part. They also maintain detailed records of all inspections and measurements for traceability and accountability.

ISO 9001 Standards

Lathe MC San Jose is committed to maintaining the highest levels of quality and customer satisfaction. To this end, they have implemented an ISO 9001 certified quality management system. This system ensures that all aspects of their production and manufacturing processes are consistently monitored, evaluated, and improved.

By adhering to ISO 9001 standards, Lathe MC San Jose is able to provide their customers with the highest levels of quality and reliability. They are also able to continually improve their processes and increase efficiency, leading to greater success and customer satisfaction.

Industries and Applications

Lathe MC San Jose is a versatile machining tool that can be used in various industries and applications. Below are some of the industries and applications where Lathe MC San Jose can be utilized.

Biotech and Medical

Biotech and medical industries require precision machining to produce high-quality medical devices and equipment. Lathe MC San Jose can produce highly precise components that meet the strict requirements of the medical industry. These components can be used in various medical devices such as implants, surgical instruments, and diagnostic equipment.

Lathe MC San Jose can machine different materials such as titanium, stainless steel, and plastics, which are commonly used in the medical industry. The tool's accuracy and repeatability make it a reliable choice for producing complex medical components.

Semiconductor and Optical

The semiconductor and optical industries require high-precision machining to produce components for various applications such as microelectronics, photonics, and optoelectronics. Lathe MC San Jose can produce precise components with tight tolerances required by these industries.

Lathe MC San Jose can machine materials such as silicon, glass, and ceramics, which are commonly used in the semiconductor and optical industries. The tool's high-speed machining capabilities make it an ideal choice for producing components with complex geometries.

In conclusion, Lathe MC San Jose is a versatile machining tool that can be used in various industries and applications. Its precision and accuracy make it a reliable choice for producing high-quality components.

Frequently Asked Questions

What types of services do machine shops in San Jose offer?

Machine shops in San Jose offer a wide range of services, including CNC machining, lathe machining, milling, welding, fabrication, and assembly. They can also provide custom machining services to meet specific customer requirements.

Can you recommend a reputable lathe machining service in San Jose?

There are several reputable lathe machining services in San Jose, including MC Machining, Inc., Bayview Plastic Solutions, and Precision Machining & Manufacturing. It is recommended to research and compare the services offered by different shops to find the one that best fits your needs.

How has lathe technology evolved in the modern era?

Lathe technology has evolved significantly in the modern era, with the introduction of computer numerical control (CNC) technology. This has enabled greater precision, accuracy, and efficiency in lathe machining, as well as the ability to produce complex shapes and designs.

What materials are commonly machined on a lathe in San Jose shops?

Materials commonly machined on a lathe in San Jose shops include aluminum, brass, copper, steel, stainless steel, and plastic. Some shops may also be able to machine exotic materials such as titanium, Inconel, and other alloys.

Are there any specialized lathe machining techniques used in San Jose's manufacturing industry?

Yes, there are several specialized lathe machining techniques used in San Jose's manufacturing industry, including Swiss-style machining, multi-axis machining, and live tooling. These techniques enable greater efficiency and precision in the production of complex parts and components.

What are the safety protocols followed by lathe operators in San Jose?

Lathe operators in San Jose follow strict safety protocols to ensure the safety of themselves and others in the shop. These protocols include wearing appropriate personal protective equipment, following safe operating procedures, and regularly inspecting and maintaining equipment to ensure it is in good working condition.