Laser Carving Machines: A Comprehensive Guide

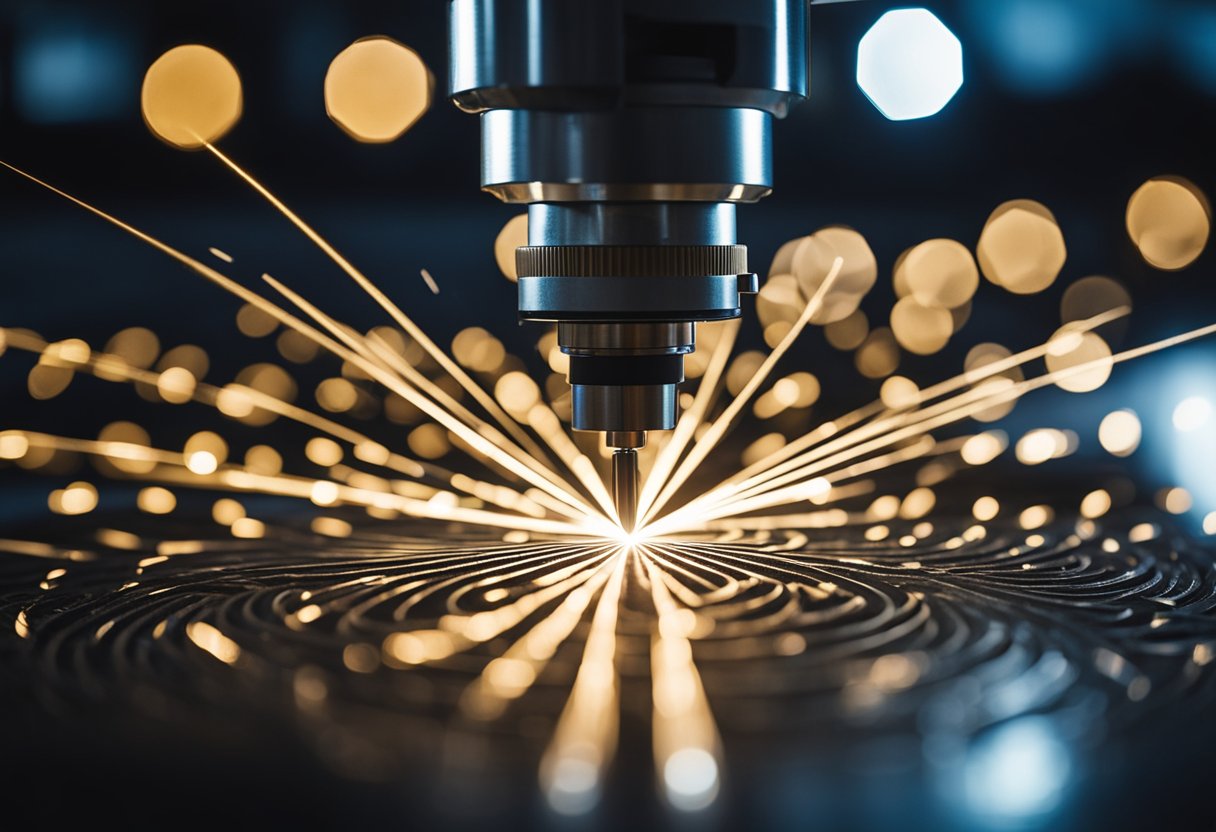

Laser carving machines are a type of laser engraving equipment that uses a high-powered laser beam to cut or engrave materials such as wood, acrylic, leather, and plastics. These machines are widely used in various industries, including manufacturing, advertising, and gift-making.

Laser carving machines are often preferred over traditional cutting and engraving methods because they offer greater precision and speed. The laser beam can be controlled with high accuracy, allowing for intricate designs and patterns to be created with ease. Additionally, the laser cutting process produces clean and smooth edges, eliminating the need for additional finishing work.

Laser carving machines come in a variety of sizes and power levels, making them suitable for both small-scale and large-scale applications. Some machines can even be used for 3D engraving, allowing for the creation of complex three-dimensional objects. With their versatility and efficiency, laser carving machines have become an essential tool for many businesses and industries.

Understanding Laser Carving Machines

Laser carving machines are a type of CNC (Computer Numerical Control) machine that uses a high-powered laser beam to cut or engrave various materials. These machines are widely used in industries like manufacturing, jewelry making, and sign making. In this section, we will discuss the different types of laser carvers, key components and functionality, as well as safety and maintenance.

Types of Laser Carvers

There are three main types of laser carvers: CO2 laser, fiber laser, and diode laser. Each type has its unique characteristics and applications.

- CO2 Laser: This type of laser carver uses a gas mixture of carbon dioxide, nitrogen, and helium to create a high-powered laser beam. CO2 lasers are ideal for cutting and engraving non-metallic materials like wood, acrylic, and leather.

- Fiber Laser: Fiber laser carvers use a solid-state laser that generates a laser beam through a fiber optic cable. They are best suited for cutting and engraving metals like stainless steel, brass, and copper.

- Diode Laser: Diode laser carvers are the most affordable and compact type of laser carvers. They use a semiconductor diode to generate a laser beam and are ideal for engraving small items like jewelry and electronics.

Key Components and Functionality

Laser carving machines consist of several key components that work together to create a high-powered laser beam. These components include:

- Laser Tube: This is the heart of the laser carver and generates the laser beam.

- Laser Power Supply: This component provides the necessary power to the laser tube.

- Mirrors: Mirrors are used to direct the laser beam to the workpiece.

- Lens: The lens focuses the laser beam onto the workpiece, creating a precise cut or engraving.

- CNC Controller: This component controls the movement of the laser beam and the workpiece.

Safety and Maintenance

Laser carving machines can be dangerous if not used properly. Safety features like interlocks, emergency stop buttons, and safety glasses should always be used when operating a laser carver. Additionally, regular maintenance is essential to keep the machine running smoothly. This includes cleaning the lens and mirrors, checking the laser power, and replacing worn parts.

In conclusion, laser carving machines are powerful tools that can cut and engrave a wide range of materials. Understanding the different types of laser carvers, key components and functionality, as well as safety and maintenance is essential for anyone looking to operate a laser carving machine.

Materials and Applications

Compatible Materials

Laser carving machines are versatile and can work with a variety of materials. Some of the materials that can be used with laser carving machines include wood, metal, plastic, leather, acrylic, fabric, stone, paper, anodized aluminum, marble, and cardboard.

Each material has its own unique properties and requires different settings to achieve optimal results. For example, wood and leather require lower power settings to avoid burning, while metal and stone require higher power settings to achieve the desired results.

Creative and Industrial Uses

Laser carving machines have a wide range of applications in both creative and industrial settings. In the creative field, laser carving machines are used to create intricate designs on a variety of materials, such as wood, leather, and fabric. These designs can be used for decorative purposes or to add branding to products.

In the industrial field, laser carving machines are used for precision cutting and engraving on materials such as metal and plastic. They are also used in the manufacturing of electronic components, medical devices, and aerospace parts.

Overall, laser carving machines are a valuable tool for a wide range of applications. With the ability to work with so many different materials and achieve such precise results, they are an essential tool for anyone looking to create high-quality designs or products.

Choosing the Right Machine

When it comes to laser carving machines, choosing the right one can be a daunting task. With so many options on the market, it's important to consider a few factors before making a purchase.

Factors to Consider

Beginner or Professional?

The first thing to consider is whether you're a beginner or a professional engraver. If you're just starting out, you may want to opt for a more affordable machine that is easy to use and has a smaller learning curve. On the other hand, if you're a professional engraver, you may want to invest in a machine that offers more advanced features and higher quality output.

Small Business or Personal Use?

Another factor to consider is whether you're using the machine for small business purposes or personal use. If you're using it for a small business, you may want to invest in a higher quality machine that offers better performance and durability. However, if you're using it for personal use, you may not need to invest as much money.

Quality and Performance

Quality and performance are also important factors to consider. You want a machine that is reliable, produces high-quality output, and is easy to maintain. Look for machines that offer high resolution, good accuracy, and a range of materials that can be engraved.

Brands

There are several brands of laser carving machines on the market, and it's important to do your research to find the best one for your needs. Some of the top brands to consider include Glowforge, Ortur LM3, Xtool D1 Pro, Xtool P2, Glowforge Pro, Neje 3, and Ortur Laser Master 3.

Top Rated Machines for Different Needs

Affordable Laser Engraver

For those on a budget, the Ortur Laser Master 3 is a great option. It's affordable, easy to use, and offers good performance for its price.

Small Business

For small businesses, the Fusion Pro is a top-rated machine. It offers high-quality output, good durability, and a range of features that make it ideal for small business use.

Professional Engraver

For professional engravers, the Glowforge Pro is a top-rated machine. It offers advanced features, high-quality output, and good durability, making it a great investment for those in the industry.

In conclusion, choosing the right laser carving machine requires careful consideration of several factors, including your skill level, intended use, and budget. By doing your research and weighing your options, you can find a machine that meets your needs and produces high-quality output.

Software and Accessories

Design Software Integration

The laser carving machine comes with software that enables designers to create and edit designs before they are sent to the machine for carving. This software allows designers to create intricate designs that can be engraved on a variety of materials, including wood, acrylic, and leather.

One of the most popular design software that is compatible with the laser carving machine is Lightburn. This software offers a user-friendly interface that allows designers to create designs easily. Lightburn also has a feature that allows designers to preview their designs before they are sent to the machine for carving, which helps to minimize errors.

Enhancing Capabilities with Accessories

The laser carving machine can be enhanced with a range of accessories that can increase its capabilities. One such accessory is the rotary attachment, which allows the machine to engrave cylindrical objects such as bottles and glasses. This attachment is particularly useful for designers who want to create personalized gifts or promotional items.

Another accessory that can be added to the laser carving machine is an air filter. This accessory helps to remove fumes and smoke generated during the carving process, which improves the overall safety of the machine. The air filter is particularly useful for designers who work in small or enclosed spaces.

Fusion Maker is another accessory that can be added to the laser carving machine. This accessory allows designers to create 3D designs that can be engraved on a variety of materials. Fusion Maker is compatible with a range of design software, including Lightburn, which makes it easy for designers to create complex designs.

In conclusion, the laser carving machine is a versatile tool that can be used to create intricate designs on a variety of materials. The machine comes with software that enables designers to create and edit designs, and can be enhanced with a range of accessories that can increase its capabilities. Whether you are a professional designer or a hobbyist, the laser carving machine is a valuable tool that can help you create stunning designs.