CNC Metal Lathe San Jose: Precision Machining Services for Your Business Needs

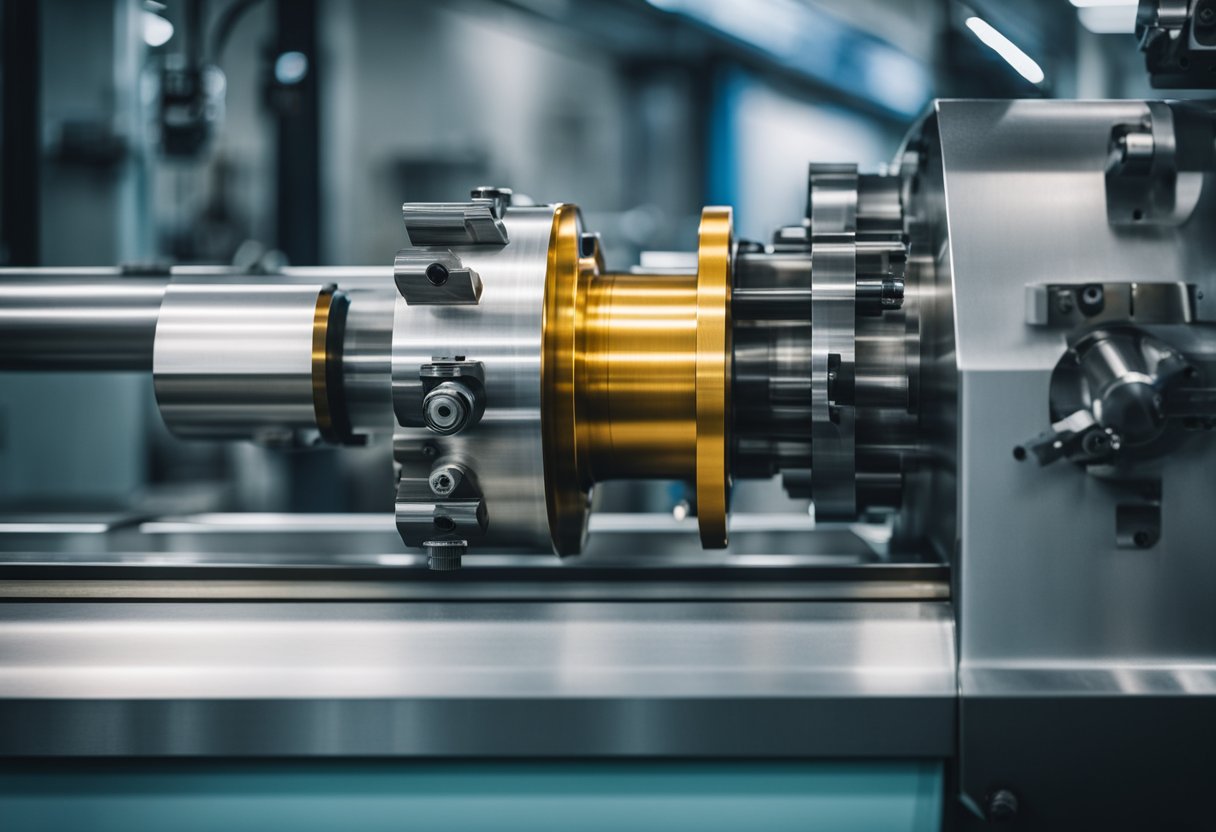

CNC metal lathes are a vital piece of machinery in the manufacturing industry. These machines are used to produce high-quality metal parts with precision and accuracy. San Jose, California is home to many companies that specialize in CNC metal lathe services. From small startups to large corporations, these businesses offer a wide range of services to meet the needs of their clients.

CNC metal lathes use computer-controlled technology to create complex parts and components. The machines are capable of producing parts with tight tolerances and intricate designs. San Jose is a hub for technology and innovation, making it an ideal location for companies that specialize in CNC metal lathe services. These businesses have access to the latest technology and equipment, allowing them to produce high-quality parts quickly and efficiently.

Overview of CNC Metal Lathes in San Jose

CNC metal lathes are an essential tool in the precision machining industry, and San Jose is home to some of the leading manufacturers and service providers in the field. These machines are used to produce complex parts and components with high accuracy and consistency, making them ideal for a variety of industries, including aerospace, medical, automotive, semiconductor, and biotech.

Importance of Precision Machining

Precision machining is a critical process that involves cutting, shaping, and finishing metal parts to exact specifications. CNC metal lathes are an integral part of this process, allowing manufacturers to produce parts with tight tolerances and intricate shapes that would be difficult or impossible to achieve with traditional machining methods. The use of CNC technology also ensures that each part is produced with consistent quality, reducing the risk of errors and defects.

Key Industries Served

San Jose is located in the heart of Silicon Valley, a hub of innovation and technology. As a result, the city is home to a diverse range of industries that rely on precision machining and CNC metal lathes. Some of the key industries served by CNC metal lathes in San Jose include:

- Aerospace: CNC metal lathes are used to produce parts for aircraft engines, landing gear, and other critical components. These parts must meet strict safety and performance standards, making precision machining essential.

- Medical: CNC metal lathes are used to produce medical implants, instruments, and devices. These parts must meet strict regulatory requirements and be biocompatible, making precision machining and high-quality materials essential.

- Automotive: CNC metal lathes are used to produce parts for engines, transmissions, and other critical components. These parts must meet strict performance and durability standards, making precision machining essential.

- Semiconductor: CNC metal lathes are used to produce parts for semiconductor manufacturing equipment, including wafer handling systems and vacuum chambers. These parts must meet strict cleanliness and precision requirements, making precision machining essential.

- Biotech: CNC metal lathes are used to produce parts for laboratory equipment, including centrifuges and microscopes. These parts must be precise and durable, making precision machining essential.

In conclusion, CNC metal lathes are a critical tool in the precision machining industry, and San Jose is home to some of the leading manufacturers and service providers in the field. These machines are used to produce complex parts and components with high accuracy and consistency, making them ideal for a variety of industries, including aerospace, medical, automotive, semiconductor, and biotech.

Technical Aspects of CNC Lathing

Material Considerations

When it comes to CNC metal lathing, the choice of material is crucial to achieving the desired outcome. The most commonly used materials in CNC lathing include aluminum, delrin, brass, steel, and copper. Each of these materials has its unique properties that make it suitable for specific applications. For instance, aluminum is lightweight and has excellent thermal conductivity, while brass is known for its high corrosion resistance and electrical conductivity.

CNC Lathe Operations

CNC lathing involves a series of operations that are executed by computer-controlled machines. These machines use advanced technology to produce highly precise and accurate parts. Some of the operations involved in CNC lathing include facing, turning, drilling, boring, and threading. Each of these operations requires a specific tool and cutting speed to achieve the desired result.

Quality and Precision Standards

Quality and precision are critical aspects of CNC lathing. Manufacturers must adhere to strict quality standards such as ISO 9001:2015, AS9100D, and 13485:2016 certified to ensure that their products meet the required specifications. Additionally, CNC lathing requires tight tolerances, which can only be achieved through precise engineering and the use of advanced technology such as CMM and Zeiss CMM.

In conclusion, CNC metal lathing is a complex process that requires technical expertise and advanced technology to achieve the desired outcome. Manufacturers must choose the right material, execute the appropriate operations, and adhere to strict quality and precision standards to produce high-quality CNC machined parts.

Capabilities of Local Machine Shops

When it comes to CNC metal lathe services, local machine shops in San Jose, CA and the Bay Area offer a wide range of capabilities. These machine shops use advanced manufacturing technologies and provide custom CNC machining services to meet the needs of various industries.

Custom CNC Machining Services

Local machine shops in San Jose offer custom CNC machining services that are tailored to meet the specific needs of their clients. They have the expertise and equipment to provide precision CNC milling, CNC turning, and 5-axis machining services. These services are ideal for prototyping and producing complex parts with tight tolerances.

In addition to CNC machining, these machine shops also offer other services such as EDM, anodizing, plating, metal fabrication, and 3D printing. These services allow clients to get all their manufacturing needs met in one place, saving time and money.

Advanced Manufacturing Technologies

Local machine shops in San Jose use advanced manufacturing technologies to provide high-quality CNC machining services. They use state-of-the-art equipment and software to ensure precision and accuracy in their work. These technologies include CAD/CAM software, CNC machines, and inspection equipment.

With these technologies, local machine shops can produce complex parts quickly and efficiently. They can also provide design assistance and help clients optimize their designs for manufacturability.

Overall, local machine shops in San Jose offer a wide range of capabilities and services to meet the needs of various industries. They have the expertise, equipment, and technologies to provide custom CNC machining services that are tailored to meet the specific needs of their clients.

Business and Logistics

Competitive Pricing and Lead Times

When it comes to CNC metal lathe services in San Jose, businesses need to ensure that they are getting the best value for their money. That's why it's important to work with a company that offers competitive pricing and reasonable lead times.

At CNC Metal Lathe San Jose, customers can expect both. The company offers affordable prices without compromising on quality. They also work closely with clients to ensure that lead times are reasonable and that projects are completed on time.

Customer Service and Support

Customer service and support are crucial when it comes to CNC metal lathe services. Clients need to work with a company that can provide expert advice and guidance throughout the entire process.

CNC Metal Lathe San Jose prides itself on its exceptional customer service and support. The team is knowledgeable, friendly, and always willing to go the extra mile to ensure that customers are satisfied. Whether it's answering questions about pricing, lead times, or quantity, the team is always available to provide expert advice and guidance.

Overall, businesses looking for CNC metal lathe services in San Jose can trust CNC Metal Lathe San Jose to provide competitive pricing, reasonable lead times, and exceptional customer service and support.

Frequently Asked Questions

What factors influence the cost of CNC metal machining in San Jose?

Several factors can influence the cost of CNC metal machining in San Jose. These can include the complexity of the project, the type of material being used, the size of the project, and the level of customization required. Additionally, the experience and expertise of the CNC machinist can also impact the cost.

How do I choose the best CNC metal lathe for my San Jose based operations?

Choosing the best CNC metal lathe for San Jose based operations requires careful consideration of several factors. These include the size of the project, the type of material being used, the level of precision required, and the budget available. It is also important to consider the reputation and experience of the manufacturer and the availability of support and maintenance services.

What are the common maintenance requirements for a CNC metal lathe?

Common maintenance requirements for a CNC metal lathe include regular cleaning, lubrication, and inspection of the machine's components. It is also important to perform regular maintenance on the machine's cutting tools and to replace them when necessary. Additionally, it is important to follow the manufacturer's recommended maintenance schedule and to address any issues as soon as they arise.

What are the key differences between a conventional metal lathe and a CNC metal lathe?

The key difference between a conventional metal lathe and a CNC metal lathe is the level of automation and precision offered by the latter. CNC metal lathes are controlled by computer programs, allowing for greater precision and accuracy in the machining process. Additionally, CNC metal lathes can be programmed to perform complex operations automatically, reducing the need for manual intervention.

Why might CNC metal lathes be considered a significant investment for San Jose businesses?

CNC metal lathes can be considered a significant investment for San Jose businesses due to their ability to increase productivity, improve accuracy, and reduce labor costs. Additionally, CNC metal lathes can be programmed to perform a wide range of operations, making them versatile tools for a variety of metalworking projects.

What are some potential drawbacks to using CNC lathes for metalworking projects?

Some potential drawbacks to using CNC lathes for metalworking projects include the high initial cost of the equipment, the need for specialized training to operate the machines, and the potential for downtime due to technical issues. Additionally, CNC metal lathes may not be suitable for all types of metalworking projects, such as those requiring a high degree of customization or those involving very large or heavy materials.